An Overhead Crane or Bridge Crane is a type of crane that uses an end truck that rides along the top of a runway beam to allow the crane to travel the full length of the runway system. They consist of a hoist to lift the items, the bridge, which spans the area covered by the crane, and a trolley to move along the bridge girder. They are complete with a pendant control station or radio remote control to operate the cranes functions (Up/Down/North/South/East/West).

Overhead Cranes can come in different types and designs whether it is a single girder or double girder. Typically, a Single Girder Cranes capacity range from ½ Ton to 15 Ton, while the Double Girder Cranes capacities can range from 20 Ton to 150 Ton.

TOP RUNING SINGLE GIRDER CRANE:

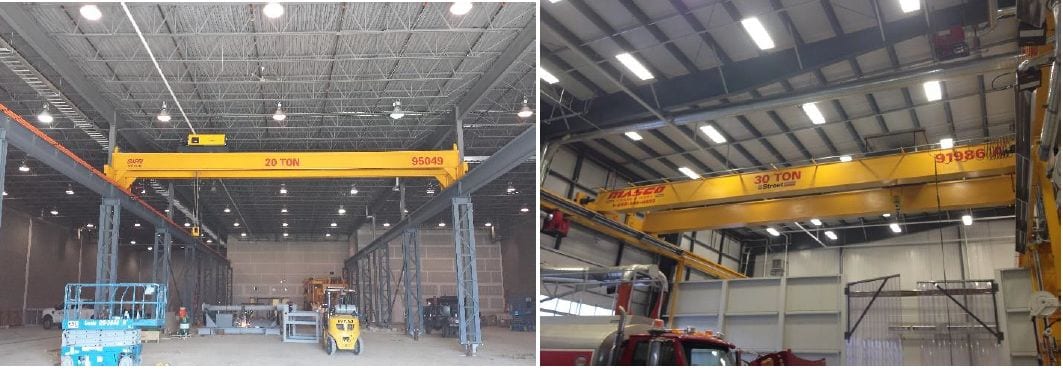

TOP RUNING DOUBLE GIRDER CRANE:

Some things to consider when purchasing your new overhead crane system:

1. The load capacity of the crane system:

• This is typically the most important feature to consider when purchasing an

overhead crane. Know the weights of the loads you will be lifting with the crane

and the maximum weight of your heaviest lift. We also recommend never to

short yourself on capacity when purchasing a crane system.

2. The height of lift:

• Usually this is the second most important specification for someone when

purchasing a new crane system. Certain lifts require a particular height to be

achieved in order to complete the lift. Whether it is loading a truck, a machine or

flipping a skid, know your max height of lift that you would like to achieve.

3. The crane span and runway length:

• Determining the span or total area of coverage that is needed is an important item

to consider when purchasing an overhead crane system. Some cranes will span an

entire facility, or just a smaller area for a workstation.

4. Free Standing System or Pre-Engineered Building (Attached to Building):

• Free Standing Crane Systems are not attached to a building structure and require

the manufacturing and installation of dedicated columns to support the crane

runway system and the crane. A Pre-Engineered system is one where the crane

runways are attached to the building structure eliminating the need for dedicated

crane columns, thus increasing floor space.

5. Crane usage and operation:

• It is important to let the crane supplier know how the crane will be used

throughout a working day, week and year. This will help determine the

classification that the crane and components will be designed to. Usually this can

be broken down to lifts per day, capacity of the lifts being performed, and

distances travelled when under load.

6. Where will the crane be located?

• This can be important for the crane supplier to provide you with a crane to suit the

application. Will the crane be located in a clean facility? Outdoors? Dusty Area?

Acidic Area?

7. Are special features required for your crane application?

• Do you require any special items or options for your crane system? Things such

as warning lights, flood lights, horns/alarms, load scales, remote controls, anticollision

devices or custom lifting beams and attachments.

8. Consult an expert:

• Masco’s team can assist with your crane design and specifications. Contact our

office and one of our team members will discuss with you the crane system and

specifications you require.